Ceramic tile installation guide for DIYers in Canada. Learn how to install ceramic tile, avoid mistakes, and maintain your tiles for lasting results.

Introduction

Importance of Ceramic Tile Installation

For very economical, long-lasting, and highly adaptable surfaces today, most homeowners resort to ceramic tiling on floors, walls, and countertops. This type of installation may easily adapt and transform any home improvement project for either a bathroom, kitchen, or living space. That elegant touch you are adding to your space comes with a material investment with proven performance under daily usage.

What sets ceramic tiles apart is the extreme durability feature. Just because they very resist scratches, moisture, and stains, they are preferred for high-traffic and high-wet areas like kitchens, bathrooms, and hallways. Other things that ensured the perpetuation of ceramic tiles as the first choice among many homeowners and businesses alike are longevity and low maintenance cost. It is extremely straightforward to conduct this process but requires precision and a level of care.

Ceramic tiles without these can be customized. They come in many colors, textures, patterns, and sizes, which might ultimately create a space that is either sleek and modern or rustic and old-worldly. A bold accent wall in the living room; a luxurious tiled shower in the bathroom-the fact is-certainly, ceramic tiles can help your design vision come to life.

Why is Ceramic Tile Installation Worth It?

Another appealing aspect of ceramic tile is that it will last a long time. Once it is installed, it will probably last for decades before requiring maintenance. That means it is a good investment for homeowners trying to add value to their property. A well-maintained floor or backsplash could do wonders for a property, especially if you intend to sell it in the future.

Moreover, ceramic tiles are also water-resistant. Best used in a wet area such as a bathroom or kitchen where water child becomes an integral part of life, it helps to avoid the warping and buckling characteristic of other flooring materials. They stay in place, even with water around them. And they are very easy to clean. Just a quick sweeping or mopping will remove any dirt and stains.

Additionally, ceramics are very beautiful. That's why it's one of the most popular choices for homeowners. They may look like natural stone, wood, or even concrete. There are many design options to suit everyone's taste and budget. Whether you want traditional subway tiles for your bathroom or more contemporary large format tiles for a sleek living room, ceramic tiles can provide the right touch in aesthetic and timeless finish in any room.

In conclusion, ceramic tile installation provides a lot of benefits ranging from an increase in property value to being very durable, low maintenance, and versatile. Under perfect installation and care, they could serve very well in the functionality and beauty enhancement of the home for many years to come.

Understanding Ceramic Tile

What is Ceramic Tile?

Ceramic tiles compose flooring or wall product from natural raw ingredients, like clay, sand, and minerals, fashioned into thin flat pieces and then underwent a high firing temperature. The firing process hardens the tiles to make them strong, waterproof, and easy to clean. They are available in many different finishes from glazed to unglazed for different applications like flooring, backsplash, and countertops.

Versatility is the cardinal feature of ceramic tiles. Almost any room in the house-from the bathroom and kitchen to living rooms and outdoor patio-can be tiled with them. Apart from their beautification purposes, they are also desired for their indispensable durability-making them one of the most widely used materials in homes and even in commercial spaces.

Types of Ceramic Tiles

Offered are many different types of ceramic tiles, and each one has its advantages according to specific applications. On the main types of ceramic tiles, they are the following:

- Glazed Ceramic Tiles: These tiles finish glossy or matte through glaze application. Glaze provides a certain beauty for the tile and also protects it against stains, scratches, and absorption of water. Most tiles are used for the walls, backsplashes, and installations of bathrooms.

- Unglazed Ceramic Tiles: Unglazed tiles don't get any yield from the protective coating of glazing; they are darker-hued, earthy, and generally have more pore spaces in comparison to glazed. An unglazed tile is terracotta, which would be rustic in design or have a natural look where placed. By the same token, an unsealed surface would need to be finished because it would be moisture and stain absorptive.

- Porcelain Ceramic Tiles: Actually, porcelain tiles belong to a category of ceramic tiles, but these tiles also get fired at a higher temperature than other ceramic tiles, rendering them denser and much less porous. These kinds of tiles have the best strength and durability, making them suitable for areas with heavy footfall and outdoors. Finishes of porcelain tiles range over many options including those fabricated to look like natural stone, wood, or marble.

- Quarry Tiles: Quarry tiles are unglazed ceramic tiles that are made from natural clay. Such tiles are most commonly used in outdoor or industrial environments because of their durability and slip-resistance properties. They are generally found in earth colors and are rougher than the other categories of ceramic tiles.

Differences Between Ceramic and Porcelain Tiles

Ceramic and porcelain tiles resemble one another in many respects, but they also differ in certain significant aspects. Both types of tiles are formed from clay, but that is the extent of their similarity; the real difference is in the material and firing.

- Composition of Material: Generally, the material that makes up ceramic tiles is clay, minerals, and water, while porcelain tiles are composed of finer clay body put under firing at a higher temperature to give them their characteristics of being denser, harder qualities.

- Durability: Compared to ordinary ceramic tiles, porcelain tiles are generally much stronger and more durable. Because of their dense structure, they are usually less absorbent, making them suitable for areas with high traffic and bathrooms, kitchens, and outside places where there can be humidity-moist conditions.

- Porosity: Ceramic tiles are usually more porous than porcelain tiles, which lead to water absorption if the tiles are unglazed. Regarding porosity, porcelain tiles are virtually impervious to water making them apt for vulnerable areas to spills and moisture.

- Cost: This usually makes porcelain tiles more expensive than ceramic. The price difference occurs due to the refinement of the materials and additional firing process. But in fact, they are effective and thus can worth an investment for areas that have to withstand better performance.

Applications of Ceramic Tiles in Home Design

These ceramic tiles can be applied for various uses in the home. The most commonly tiled areas are:

- Floor: The tile flooring is best for rooms with heavy foot traffic or moisture ingress like kitchens, baths, entryways, and hallways. Perfect for use in high traffic areas, they provide the needed durability and are easy to maintain.

- Wall tiles: Wall applications such as backsplashes in bathrooms, wall tiles in kitchens, and accent walls are usually done with ceramic tiles. They are also very good at preventing anything moist from getting into the walls or anyone's stains, which are perfect for splash-splash areas.

- Showers and bathtubs: This type of tile will usually tile shower walls, the area around bathtubs, and sometimes even bathroom floors themselves, because of its resistance to water and very good general durability.

- Countertops: Ceramic tiles can generally be utilized as countertops in kitchens and bathrooms because they afford defense against stains, scratches, and hot items. This makes them realistic surfaces for areas of high use.

- Outdoor Spaces: Porcelain ceramic tiles especially can be used in outdoor spaces, such as patios, walkways, and pool decks. They provide high density and water resistance, which makes them suitable for climate exposure.

Tools and Materials Required for Ceramic Tile Installation

With your ceramic tile installation project, it is necessary to gather all required tools and materials. It is important to have the right tools ready for transportation, as everything will be much smoother and faster. Following is a comprehensive list of essential tools and materials needed, including optional items to make jobs much easier.

Essential Tools

1. Measuring Tape

In every tile installation, it is necessary to have a measuring tape with you. This is where you will measure all your areas wanting tiles to be installed. The space that the tiles gave allows them to be accurate when measuring to cut them exactly and for maintaining a balanced layout. Measures should be confirmed before cutting tiles.

2. Tile Cutter

For straight cuts, a manual tile cutter is indispensable. It uses a scoring wheel to score the surface of the tile, and a snapping mechanism breaks it along with the score line. Tile cutters are best for making simple cuts on ceramic tiles, edge pieces, and small adjustments. These tools are easy to use and able to offer clean, straight cuts.

3. Wet Saw

For more complicated cuts, such as diagonal cuts or cuts around fixtures (like pipes or electrical outlets), a wet saw is highly recommended. A wet saw uses a diamond-tipped blade and water to help cool the blade. This is very ideal for cutting ceramic and porcelain tiles with precision. Wet saws are typically more expensive than tile cutters, but they are well worth the extra investment in bigger projects with a lot of more intricate cuts.

4. Notched Trowel

This trowel is designed for applying adhesive, or thin-set mortar immediately onto the surface where the tiles were laid. The notched edge of the trowel helps to make an even spread of the mortar to form the appropriate amount of adhesive for holding the tile to the surface. The size of the trowel's notch depends on the size of the tile. Most likely larger tiles will require a trowel with larger notches.

5. Tile Spacers

Tile spacers are small plastic pieces that are placed in between the pieces of tiles to maintain the right gaps between them. They are the reason why the tiles will all have the same spacing and, thus, have the grout line consistent between each tile. Depending upon the required grout width, different sizes can be used (commonly 1/16', 1/8', or 1/4'). It's very important that the spacers be used at uniform intervals during installation because this gives the very professional and, therefore, very uniform look.

6. Rubber Mallet

The rubber mallet taps tiles carefully into space once they are laid in the adhesive. This enables both alignment and proper seating without any surface damage to the tile itself. A mallet can also help remove air or empty spaces present beneath tile substrate, assuring strong adhesion between the tile and the substrate.

7. Level

A level is an important tool to ensure that your tiles are laid straight and level. One should use the level to check the alignment of each tile as one goes, especially in the early stages of installation. A perfectly level surface is essential to achieving a smooth, even floor or wall. If it is not level, it can cause the tiles to shift or become misaligned, leading to an uneven finish.

Materials Needed

1. Ceramic Tiles

The most crucial material for your tile installation project is the tiles. Make sure tiles are suitable for the location in which they are installed; there are some things to keep in mind for tile use such as tile size, colour, texture, or pattern. If you are going for bigger area tiles, remember to keep some extra tiles for later use when any of your tile might break during installation.

2. Tile Adhesive or Thin-Set Mortar

Tile glue is a cement-based product known as thin-set mortar. They are used to connect the tiles to the surface, and it comes in pre-loaded formats, as well as powder forms. Simply mix powder form with water, while premixed thin-set mortars are ready for application right after coming from the container. Aside from above mention points for selection of right adhesive, make sure that the adhesive you choose is safe for ceramic tiles, and for the certain kind of surface, be it floor, wall or countertop

3. Grout

Then grout is used for filling the spaces in between after the set of adhesives has set firmly the tiles. It comes in two forms i.e. sanded and unsanded grouts. For wider gaps usually greater than 1/8 inch, they use sanded grout, on the other hand, unsanded grout is used for thinner joints which are lesser than 1/8 inch. There is a wide range of colors that grout can be obtained in to match or even contrast your tiles for the aesthetic custom look.

4. Grout Sealer

After doing grouting, sealing is important to be done for grout protection from stains, moisture, and dirt. Grout sealer is put on grout lines and stops water and dirt penetration, thus keeping grout intact and looking clean. Cleaning becomes much easier since sealed grout is less prone to staining.

5. Primer or Surface Preparation Products

There are cases where a primer or surface preparation product will be needed, most especially when tiling onto scorching, uneven, or unsealed surfaces. A primer helps improve tile adhesive adhesion while enhancing a more stable base for installation. It's also important to use bonding primers while tiling over old linoleum or laminate to ensure the bond stays strong.

Optional Tools for Specific Needs.

While the above tools will mostly suffice for general ceramic tile installation, there are a plethora of tools that can add efficiency to specific tasks or enhance the overall finish.

- Tile Nippers: Preferable for doing small irregular cuts around the pipe, the light switch, etc. They are ideal for detailed trimming in instances where the tile cutter and wet saw are not appropriate.

- Grout Float: For spreading grout over tiles, pressing grout into the spaces in between the tiles, and ensuring that it is of even application surface.

- Tile Saw Blade: If you are using a wet saw, make sure you have the right blade for ceramic tiles. There are special blades for cutting ceramic that will give you a cleaner and more precise cut.

Surface Preparation for Ceramic Tile Installation

Surface preparation is the single most important factor as it is directly linked to the success and durability of the tile installation. One can easily damage the tile installation by rushing this step or without it. Cracked tiles, loose or missing grout, and uneven surfaces usually result as a consequence in the future. The process of surface preparation is the backbone for strong adhesion of installment whether it's a bath floor, a kitchen backsplash, or any other surface.

Check-the Condition of Substrate

The first step before preparing a surface for tile installation is looking at the substrate- that is the surface you shall install the tiles on- concrete, plywood, drywall, cement board or, indeed, a floor with tiles already laid on it. Each type of substrate will have its requirements. But in general here are the basic requirements of sites under consideration for tiling.

- Clean- Dust, grease, old adhesive, paint debris, etc. should be removed. A clean surface encourages fast adhesion of the tile adhesive.

- Dry-Moisture interferes with bonding and gives problems such as mold or mildew. The substrate must be dry.

- Flat: Using a level, check the area for high spots or indentations. Areas should not deviate more than 1/8 inch over 10 feet.

- Stable: A wobbly or flexible substrate leads to cracked tiles. Ensure it is well-supported and doesn't flex under pressure.

For wooden subfloor, ensure the thickness is nothing less than 1 1/8 inch and constructed with good joist spacing. When it comes to bathroom tile installation, cement backer board or waterproof underlay is essential to help avoid water damage especially in the shower or wet areas.

Clean and prime the surface

Once the substrate inspection task is completed, commence with a thorough cleaning. Sweep and vacuum any dust; scrub grease or adhesive residue with mild detergents or degreasing agents. For the wall, it might require a light sanding or roughening of glossy paint surfaces so as to gain good grip during mortar application.

The application of a bonding primer comes in handy when you have very porous or dusty surfaces like drywall or plywood. It helps to:

- Increase the adhesion of thin-set mortar

- Seal the surface so that it does not suck moisture from the adhesive

- Create uniform and equal substrate to have consistent drying

Allow the primer to thoroughly dry before going ahead with the installation of the tiles. This is usually between half an hour and an hour, depending on humidity and the product used.

Leveling and Repairing the Surface

It is vital that a surface is level and smooth. If the substrate is uneven, it can cause tiles to lift over time, rock, or even crack. With a long spirit level or laser level, check the area for unevenness. Any dips or bumps discovered should be treated as follows:

- Use a self-leveling compound to fill low spots on floors.

- Patching compounds can be used to fill cracks and holes on a concrete surface.

- Sand smooth on high plywood or backer boards.

If doing a floor, apply crack isolation membranes to keep existing cracks from transferring through the tile. This is most commonly applied on concrete floors because they have the tendency to expand and contract against temperature changes.

Make sure the surface is moisture-resistant and adequately supported in case of walls installations, especially bathrooms. Additionally, a waterproof membrane such as RedGard or the like minimizes the likelihood of water damage being incurred on the walls but will also afford some protection in areas like showers.

Draft the Layout

It is necessary to plan the layout for the tiles before installing any adhesive. Poor layout planning usually results in awkward cuts, or at least an uneven line of tiles. Here is effective planning:

- Dry fit your tile starting from the center of the room or wall and working toward the edges. This will visually show you what the final configuration will be and allow you to adjust as necessary.

- Mark your reference lines on the surface with chalk lines; this will help guide you in keeping your rows straight as you install.

- Avoid very thin slivers of tile at the edges; adjust your starting point so that you will end with at least half a tile at each end. This not only looks better but gives a much stronger, more stable edge.

- Finally, if your design includes borders, inlays, or patterns, take the time to measure and mark out how they will go. This early decision reduces cutting mistakes and gives a more professional finish.

Step-By-Step Tile Installation

With well-prepared area, it is time to cope with the real installation process. This stage requires patient, precise, methodical applications to ensure your tiles are laid at an even, secure, and attractive angle. In this step-by-step guide you would find the complete process of installing ceramic tiles, suitable for floors or walls.

Step 1: Dry-Lay Your Tiles for Layout Precision

Before placing any adhesive, the first step is dry-laying the tiles to see how the layout looks. This gets you a vision of how the tiles will fit, and at this point you can before any bad cuts at edges or corners.

- For instance, if laying in a room: from the middle of the room or wall out toward the edges.

- Use spacers to simulate grout lines.

- Walls should not have a border without being covered with at least half a tile.

- Mark the middle and perpendicular lines with a chalk line or pencil to guide your first rows.

This step helps you confirm the best starting point and prepares you to be very efficient once the adhesive is laid.

Step 2: Mix and Apply Tile Adhesive (Thin-Set Mortar)

With your layout set, apply your tile adhesive now. Instructions for mixing your thin-set mortar by the manufacturer should be followed. In general:

Mix powdered thin-set in water with a drill mixing paddle and mix until you achieve peanut butter-like consistency, then allow it to slake (rest) for 5-10 minutos and remix before use.

To apply:

- Spread the mortar with the flat side of your notched trowel, coating the entire surface.

- Then comb it with the notched side, holding the trowel at an angle of 45 degrees.

- Do not apply mortar at sections larger than about 3' x 3' at a time, since you need to lay tile within 10-15 minutes after spreading it.

This notched application ensures the right mortar depth and good tile adhesion. Don't skip the combing-it allows air to escape beneath the tile for a firm bond.

Step 3: Set the Tiles in Place

Once your mortar is on the surface you can now set your tiles:

- Press each tile down into place with a tiny twist in order to achieve a better contact.

- By Solely tapping tiles with a rubber mallet, level up and clear any air from the tiles.

- Make space between tiles using tile spacers to maintain equal grout lines.

Control levels frequently to confirm that tiles are even. In cases of too high or low in place tiles, lift and adjust the mortar and reset. Repeat outward from your center line, section by section.

Step 4: Cut Tiles to Fit Edges and Obstacles

You will eventually reach the walls, corners, or heating units, and here or there, you may need to cut the tiles to shape or size. Different cutting tools apply, depending on the cut:

- For straight cuts: Manual tile cutter.

- For curve or odd shapes (around pipes, outlets, etc.): A wet saw or tile nippers.

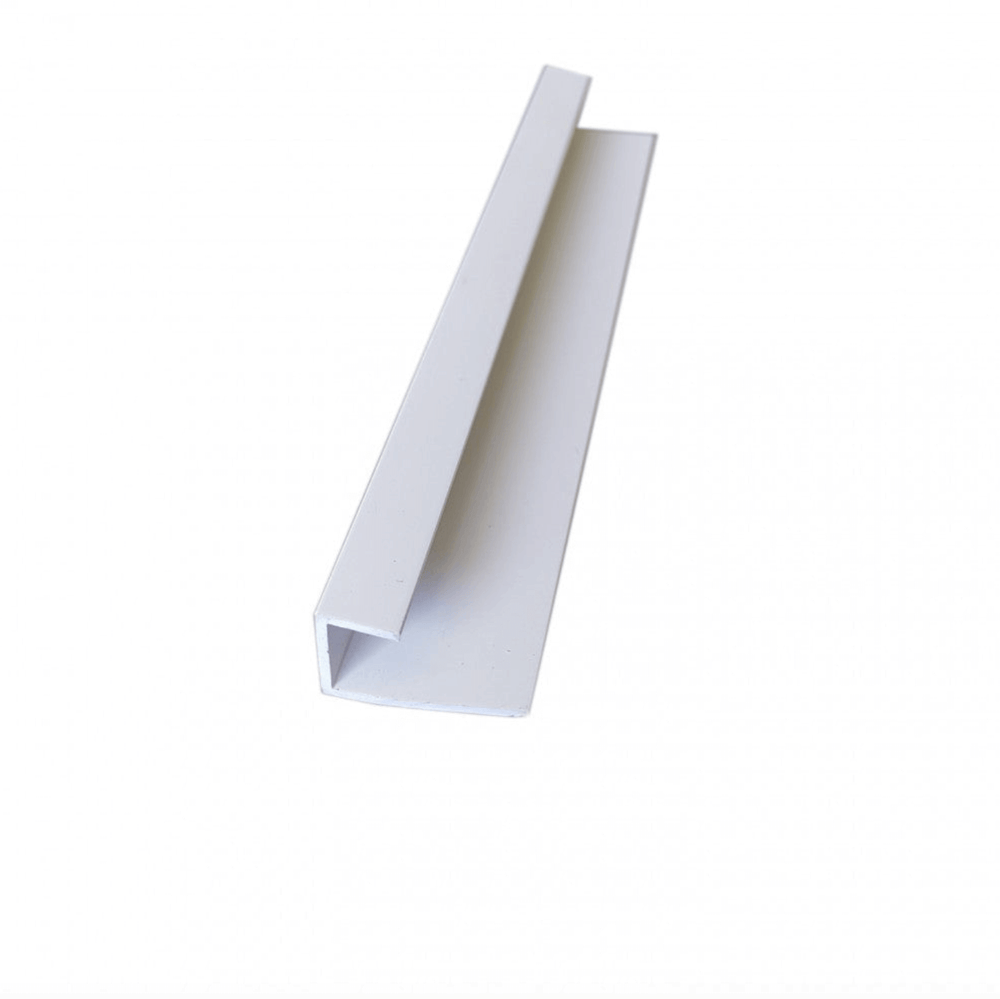

Measure two times, cut once, to avoid wastage of tiles. Exposed tile edges (e.g., on the ends of a backsplash) may require finishing with either a tile edge or trim strip for clean looks.

Step 5: Leave it to Cure

Once all the tiles are put in place, leave the tile adhesive to cure accordingly. Generally, this takes about 24 hours although, as always, refer to the instructions of your mortar.

- During this time, do not step on or touch tiles.

- Do not grout until the adhesive is completely dried.

-

Curing is critical. If rushed, your tiles have the potential to shift, or even come loose, later on.

Step 6: Grout between Tiles

Now that your adhesive is cured, it is time to grout the joints in between your tiles. Choose the right grout, sanded or unsanded, according to the size of the gap between your tiles.

Steps for grouting:

- Mix grout according to the guidelines provided by the manufacturer.

- Using a rubber grout float, press grout diagonally into the joints to fill spaces completely.

- Holding the float at an angle of 45 degrees, scrape excess grout across the tile surface.

- Let the grout sit for about 10-15 minutes, then:

- Wipe the haze and smooth the joints with a damp sponge.

- Change your water and rinse your spongelight regularly.

Set aside to cure for 24–72 hours depending on the type of grout used; while curing, keep the grout from any contact with water.

Step 7: Seal the Grout (Optional but Recommended)

When the grout has dried, apply the grout sealer. It is to prevent it from stains, water, and mold. The last step has a greater significance concerning bathrooms that are tiled and kitchens that are often subjected to moisture and spills.

- It can be sealed between grout lines with a little brush applicator or sponge.

- Let soak in, then wipe clean with a clean cloth any excess.

Sealing makes sure that your investment keeps up its neat look for years and does not fade or wear.

Common Mistakes No One Should Make While Installing Ceramic Tile

Even professional DIYers make mistakes sometimes when installing ceramic tile- some seemingly small, which go forth to warrant colossal problems like cracked tiles, unevenness, and premature wear. In what to do is as important to learn as in what not to do. Therefore, the following rental will put in clear light the widely committed ceramic tile installation errors and how to avoid them in order to achieve an impeccable long-lasting result.

1. Poor Surface Preparation

This is listed as number one of the causes of failed tile installations. Whatever good your tile and adhesive are, if a clean, dry, level, and structurally sound surface is not there, that installation pattern will never get off the ground.

What to avoid:

- Tilting upon a loose or crumbling subfloor

- Installing over glossy or oily surfaces

- Ignoring dips, cracks, or bumps

How to prevent it:

- Always inspect and prep the surface, no exceptions.

- Use leveling compounds or cement boards if needed.

- Apply primer or bonding agents on hard-to-do surfaces.

Skipping proper preparatory work can cause tiles to come off, crack, or make for an uneven finished surface.

2. Using the Wrong Adhesive

All tile adhesives are not the same. Using the wrong type for whatever reason-whether it be that it's incompatible with the surface or it's just not strong enough for ceramic-will have consequences in the form of tile slippage and bonding failure.

What to avoid:

- Mastic or glue for the walls used on the floor tiles

- Premixed adhesives on outdoor or wet applications

- Incorrect mixing of powdered thin set

How to prevent it:

- Choose a quality thin-set mortar appropriate for ceramic tiles and application-walls, floor, shower, etc.

- Follow mixing instructions for correct consistency and performance.

3. Uneven Tile Layout or Spacing

Badly set out tile layouts produce ugly cut tiles, crooked lines, and distracting visuals- especially in smaller rooms or in patterned designs.

What to avoid:

- Tiling blindly without prior layout planning or marking out guides

- Grout lines being unequal due to spacing being determined by the eye

- Ending up with very small slivers of tile at the edge of the room

How to prevent it:

- Dry tile and measure before installing.

- Use spacers every time.

- Mark out lines with chalk to stay true.

- Base your layout on the center so that it looks symmetrical at the edges.

- It'll hurt your project immeasurably if even minor deviations are picked out by the eye.

4. Hurrying Through

Tiling is not racing. Rushing any part of the process-from laying tile to grouting-can lead to disastrous results: poor bond, slippage, or even bodily injury.

What to avoid:

- Covering too large an area at a time before laying the tile

- Walking on tiles before the adhesive has set

- Grouting prior to the mortar fully curing

How to prevent it:

- Stick with manageable working sections (3' x 3' is ideal).

- Always allow proper drying/curing times as per product specification.

- Do not hurry through cleanup and sealing.

It is said that haste makes waste, and that is so very true in this case. Cutting corners today will earn you a call back tomorrow.

5. Poor Grouting and Cleaning

Grout is used for its structural and aesthetic purposes. If you either apply or clean it incorrectly, the result will either be said to look sloppy or will degrade prematurely.

Things to Avoid:

- Letting grout haze remain over the tile for too long

- Choosing the wrong type of grout (sanded grout on thin joints)

- Avoiding grout sealing, particularly in wet zones

Things to Remember:

- Grout should be pushed into joints in a compact manner, while the application should be diagonal.

- Grout should then be wiped off with a damp sponge.

- Also, seal the grout upon curing, mainly for kitchens or bathrooms.

- Otherwise, it's just a grout repair issue with cracks, stains, or water damage.

6. Not Using Expansion Joints or Movement Accommodation

Ceramic tiles are rigid construction materials and will respond to expansion and contraction caused by temperature fluctuations, moisture, and structural movement.

Things to Avoid:

Installing tiles against walls or cabinets too tightly

Neglecting to consider the provision of expansion joints in a large tiled area

Using rigid grout in the perimeter gaps instead of flexible caulking

How To Avoid It:

- Leave a gap of 1/4-inch all around between the tiles and fixed objects.

- Use silicone caulk on all edges and changes of plane (corners).

- And in large rooms, expansion joints or breaks in tile runs must be in place.

- Failure to heed movement accommodation will surely lead to cracking, buckling, or lifting.

Avoiding these common pitfalls is key to a professional-quality ceramic-tile installation. Understanding the why of these mistakes occurring-and how to avoid them-can save you time, money, and a lot of grief.

Post-Installation Care and Maintenance Tips

1. Wait for complete curing time

After grouting and sealing, if necessary, you should really allow everything time to cure before it is subject to normal use.

Why it matters:

- If walked upon too soon, newly installed tiles can shift or even crack because the adhesive bond beneath is disturbed.

- Not properly cured grout tends to become powdery, discolored.

What to do:

- Don't walk on floor tiles for 24-48 hours after grouting.

- Keep heavy furniture off for at least 72 hours.

- Let grout set for maximum before turning on water for wall tiles, especially in showers.

- Inquire product-specific recommendations for adhesives and grout.

2. Sealing up the Grout and (if need be) Tiles

As a rule, ceramic tiles are non-porous; however, grout is porous and tends to absorb moisture, dirt, and stains.

Why sealing?

- To prevent discoloration and mould growth, especially in wet areas.

- To make the grout easier to clean.

- It prolongs the longevity of the installation.

How to do it:

- Use penetrating grout sealer.

- Apply it with a small brush, a roller, or an applicator bottle.

- Let it dwell for 5 to 10 minutes, and then wipe off excess.

- Reapply every 12 to 24 months, depending on traffic and moisture levels.

Natural stone tile or unglazed ceramic probably need it as much as any other tile.

3. Cleaning Tips for Daily and Weekly Usage

Regular cleaning keeps your ceramic tiles looking their best; it also helps to prevent the accumulation of grime that may abridge your grout and cause long-term damage.

What to do:

- Sweep or vacuum floors on a daily basis to clear dirt and debris that could scratch the tile surface.

- Mop with a pH-neutral cleaner weekly (neither bleach nor vinegar).

- Use a soft, damp cloth or sponge to wipe down wall tiles regularly, especially in kitchens and bathrooms.

Don't:

- Use wax cleaners, oil soaps or very harsh acids

- Let spills sit—especially acidic ones like juice, vinegar or coffee.

- Steel wool or abrasive pads that can scratch the surface should not be used.

4. Grout Maintenance

If grout is left neglected, even the best sealers will eventually fail. Periodically inspect your grout for anything that may be cracks, chips, or growing mold.

For maintenance:

- For staining, use a grout-specific cleaner or a baking soda paste with a soft brush.

- If the grout appears discolored or broken, then re-grouting is often the easier and cheaper option than replacing tiles.

- Check for mold in bathrooms or wet areas and apply the anti-fungal treatment as necessary.

- Grit lines in high-traffic areas, such as entryways/ showers, need to be cared for as much as the tile themselves.

5. Repairing Cracked or Loose Tiles

Excessive preparation and care have gone into making sure that tiles stay stable and stuck into place, yet at times even the best installations may face failure through looseness, chipping, or cracking. Addressing these repairs early will help alleviate any further damage.

To Repair:

- Gently remove the damaged tile, chiseling with a hammer.

- Scrape out the old adhesive and grout.

- Apply fresh thin-set mortar and replace the tile.

- Re-grout around the tile and let it set.

- Always keep a few extra tiles from your original batch for any future repairs needed.

6. Seasonal and Environmental Considerations

For Canada, where temperature differences can be extreme between the seasons, it is important to consider how these variations affect tiling installation.

Things to keep in mind:

- Temperature fluctuations: The thermal expansion of tile will cause small shifts due to such temperature changes. By timely installation of properly designed expansion joints and using flexible caulk these shifts can be accommodated, thus preventing cracks.

- Frost conditions: Outdoor installations shall only be done with frost-resistance ceramics and non-porous grout.

- Humidity maintenance: Use an exhaust fan in the bathroom to combat mold and mildew, and keep grout sealed.

Being knowledgeable about your local environmental conditions will ensure that your tile installation can withstand seasonal stress and retain integrity throughout the seasons.

Final Thoughts

Installing a ceramic tile makes stressful but rewarding projects well worthy, in which these tiles provide beauty and durability to the home with their additional value. Besides preparing the surface, yet all the different steps such as placement, grouting, and ongoing care, add up to the final result. Following thorough guidelines, avoiding common mistakes, and keeping the tiles maintained will ensure you reap the benefit of flawless ceramic tiles for many years to come.

Common Ceramic Tile Installation FAQs

Q1: What is the best surface for installing ceramic tile?

The ideal surfaces for ceramic tile are clean, dry, level, and stable-such as cement backer board or concrete. Avoid using wood or uneven subfloors without proper prep.

Q2: Is it possible to install ceramic tiles on top of the old ones?

Yes, but only when the tile is in good condition and is level, clean, and properly attached. Before using thin set mortar, apply a bonding primer.

Q3: How much time does it take for the adhesive for ceramic tile to dry?

Generally, most thin-set mortars need 24 hours to achieve complete curing. However, one must check for specific drying times in the manufacturer's instructions before grouting or walking on tiles.

Q4: Is there a need to seal ceramic tiles?

Glazed ceramic tile usually does not need sealing, but grout should be sealed, particularly in bathrooms or kitchens, to prevent staining and moisture.

Q5: What is the difference between sanded grout and unsanded grout?

Sanded grout is for joints more than 1/8" in width; unsanded grout is used for narrow joints or delicate surfaces, such as polished tile or glass.